New CLO Drivers claim big advantages

This paper compares the claimed advantages of CLO drivers with simple standard constant output solutions for a number of typical use cases and LED platforms in both office and industry. CLO drivers are emerging on the market as a solution to increase the LED lifetime and to promote use of ‘cheaper’ LED packages with reduced lumen maintenance properties. It can be shown that a “KISS” solution (keep it stupid simple), like ETAP’s long term lumen stability, has proven to still outperforms CLO both in terms of lighting quality and energy cost.

Understanding CLO Drivers and the limitations

First, the limitations of CLO should be well understood:

- CLO works by a time based boost of the driver output current in a pre-programmed linear or piecewise linear fashion. Most drivers are restricted to a maximum current increase of 30% (70% to 100%). The compensation curve has to be programmed in advance by the luminaire manufacturer.

- CLO as a justification to declare L100 implies that all depreciation mechanisms have been taken into account. This includes LED depreciation (LLMF), but equally well LED mortality (Cy), degradation of any optical active parts and finally environmental effects (LMF/RMF). The latter poses an issue already, as environmental effects cannot be declared as 1: RMF/LMF are application dependent (maintenance scheme & time frame) and generally not known to the luminaire manufacturer.

- LLMF can be estimated from LM-80/TM-21, but this method has reached practical limits: with technology advances – extrapolation quality is increasingly being affected by growing uncertainties and noise, and real LED behavior can deviate substantially from TM-21. Also, as the LLMF represents median values (B50), the L100 level from a CLO implementation can never be declared as B0!

- CLO does not measure actual output levels. Hence, even with CLO enabled drivers the light output can deviate substantially from the projections, meaning CLO is never a guarantee for MF = 100%

How we initiated our comparison.

For the comparison, we have used current world LED data from ETAP’s ceramic 3535 high power platform and EMC/composite 3030 medium power platform. As a typical ‘mainstream’ LED, we have taken the same performance data and flux bins, but use an LLMF of L80B50 at 50khrs with intermediate temperatures.

We have also made some further standard industry assumptions:

- We assume that the mainstream LED exactly follows the TM-21 projection, reported in controlled environments (very optimistic!)

- The other optical parts of the luminaire do not degrade (the perfect world again!)

- For LMF/RMF we adopt a linear decrease from 100% to 90% at EOL. This is not completely true if a periodic maintenance scheme is employed. On the other hand, 90% is optimistic for industry – but we will use the same value here because lower maintenance factors are out of reach for most of today’s CLO drivers anyway.

Comparison Scenarios

The different scenarios that are compared are respectively:

- – Drivers with constant output and HQ LEDs with stable LLMF – this is ETAP’s present implementation

- – A naïve (and worst case) implementation (CLO1) in which the current from case 1 is programmed into the driver, together with a 80% => 100% compensation curve. Obviously, the output level will be too low already from the start. Also, this method tries to compensate for L80 but not for RMF/LMF.

- – Same as case 2, but now the pre-programmed current is correctly biased for an initial output level of 100%. Still, no compensation for RMF/LMF (CLO2).

- – The compensation curve is 70% => 100%, to include RMF/LMF (note that the CLO is now on its regulation limit). The set current is biased accordingly to set the initial level to 100%. Theoretically, this scenario is the only correct way to implement CLO (CLO3).

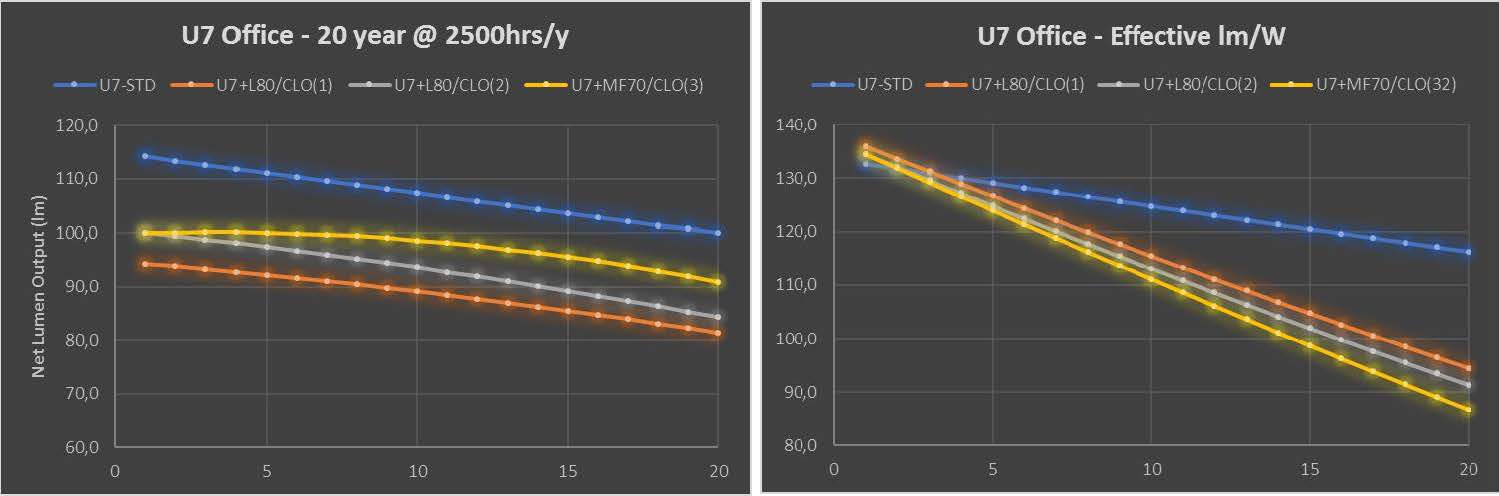

In all scenarios we consider a 20 year period with a 2500hrs/year use case (typical office). The electricity rate is AUD 0.12/kWh but we include a 2.5% increase each year. For apples for apples comparisons, we not only look at the total energy cost over the period, but also at the energy cost per lumen (comparable to the W/m²/100 lx metric)

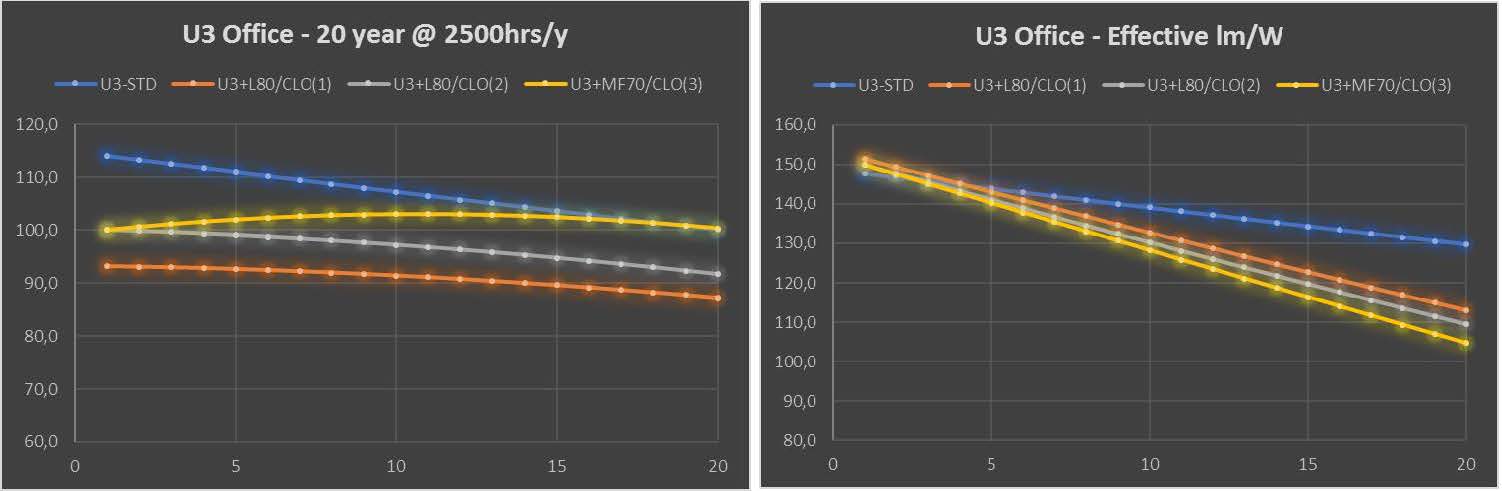

The following graphs show the performance levels (in terms of prescribed lux levels) and effective efficacy – i.e. initial lm/W corrected by MF over the project lifetime.

CASE 1 – ETAP U7 with 3535 HP LED in Office

Because of the more concentrated power density in HP applications, the nominal Tj for this example is situated in the range 60-65°C (Corresponding to U7 temperatures)

When looking at energy costs – case 2 (CLO1) seems the most economical – however the most economical – although this approach under performs over the whole project lifetime. Looking at normalized energy costs (wrt lux levels) – the ETAP fixed output is the clear winner – about 20% cheaper than the correct CLO3. The gain is even larger when looking at CLO2 – the method without LMF compensation mostly implemented today. All CLO strategies fall below target over the project lifetime.

Accumulated energy costs for a typical HP luminaire ∼3300lm @ EOL

| Energy Cost | Energy Cost/Lux | |

| STD | 219,53 | 205,10 |

| CLO(1) | 200,02 | 226,15 |

| CLO(2) | 241,49 | 260,11 |

| CLO(3) | 231,93 | 238,31 |

Also interesting to note the dramatic decrease in system lm/W for CLO

CASE 2 – ETAP U3 with 3030 MP LED in Office

This case is similar to the previous example – except that now a MP platform is used (most common solution today for office luminaires). As the power density is much lower – all luminaires are designed around low LED temperatures (typ. 40-50°C) and very modest current densities (~250-300mA/mm²).

The relative trend is similar – though somewhat less pronounced due to the very low temperatures involved. CLO can provide true L100 if also LMF/RMF is compensated (CLO3) – which is unfortunately never the case. Also holds only under ideal assumptions as mentioned before. Accumulated energy costs for a typical MP luminaire ~3000lm @ EOL

| Energy Cost | Energy Cost/Lux | |

| STD | 184,36 | 172,39 |

| CLO(1) | 167,24 | 184,02 |

| CLO(2) | 181,48 | 187,80 |

| CLO(3) | 197,07 | 193,22 |

Remarkably, the fixed output solution is still the most economical – despite its slightly over sizing across the full course of the project duration. In this example – the correct CLO implementation (CLO3) is the most expensive.

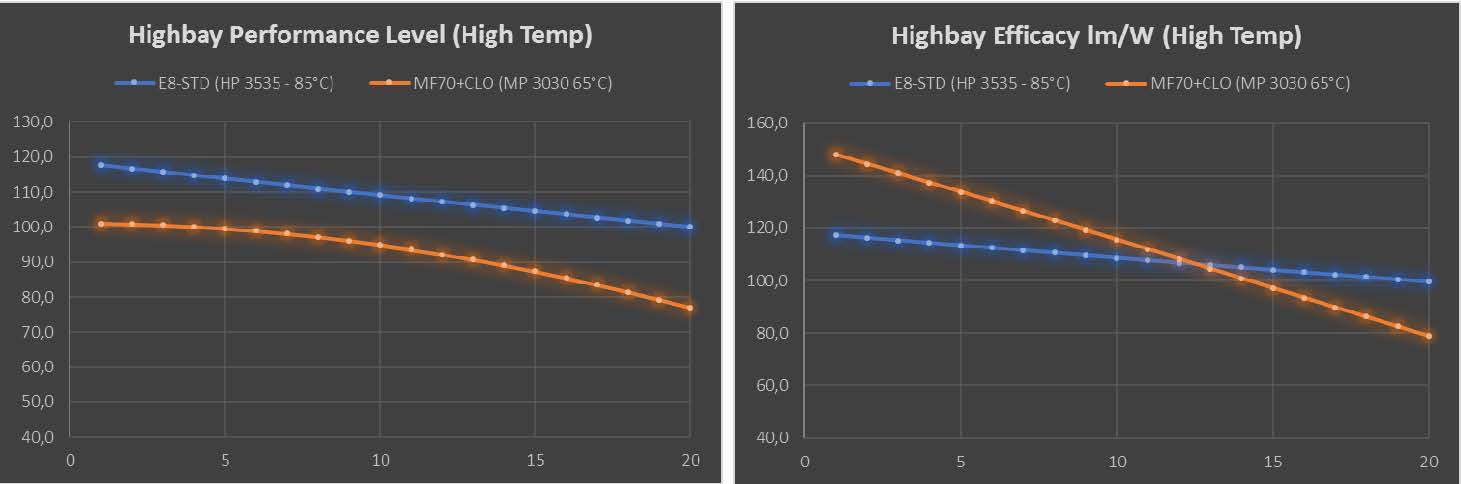

CASE 3 – Highbay luminaire HP vs. MP+CLO in Industry

ETAP highbay luminaires (E8) are fitted with HP LEDs, which are not the most efficient on the market and at the same time more expensive than MP in terms of cost per lumen – still they are amongst the most robust LED packages on the market making them very well suited for harsh environments and elevated temperatures coupled with long useful lifetimes. This example compares an E8 solution with a MP counterpart complemented with CLO (CLO3). Highbay luminaires have typically higher power densities and operating temperatures. Junction temperatures are around 85°C for the E8 and in the range 60-70°C for MP.

(note again that the RMF/LMF of 90% is very optimistic for an industrial environment – but the maximum that can be fully compensated by CLO)

Here the temperature driven acceleration effects in the MP package are clearly noticed and the L80 based compensation curve does not succeed to maintain the 100% level.

Accumulated energy costs for a small highbay luminaire ~5200lm @ EOL

| Energy Cost | Energy Cost/Lux | |

| STD | 394,27 | 362,76 |

| MP+CLO MF70 | 330,69 | 358,04 |

In this example, the total energy costs for the fixed and fully compensated CLO solution are comparable due to the initial efficacy advantage of the MP package. However, light levels remain below target and thus true CLO is not accomplished. The situation is worsens when the true LLMF behavior starts to deviate from the theoretical TM-21 predictions – as is often observed with less expensive MP packages.

CONCLUSION

In all the examples presented – even under ideal assumptions – CLO does not offer cost saving advantages over well designed constant output solutions based on LEDs with a stable (and provable) LLMF. Most CLO strategies will not succeed in preserving true constant light output levels either – so the term is misleading giving a false sense of quality to the customer. Furthermore we have looked at energy consumption only – given the fact that CLO drivers will always be more expensive than fixed output drivers, there will never be any payback associated with this added cost.

This document has been extracted from ETAP Lightings “CLO in Numbers” report 2019