Even the government questions the true value of Li-ion as the battery type continues to be recalled, cause fires and are a challenge to be recycled. Hyundai & LG Energy Solutions as well as their chosen battery recyclers are finding these troubles now as the recall has caused a great mass of battery waste to be received.

Electric vehicles were a huge vision of the future to reduce energy costs and increase savings. This has reached Australia now where manufacturers like Hyundai have begun to sell this amazing technology. However several product recalls pose a problem for our country and for others following the same path.

Hyundai has started pulling batteries from nearly 1000 electric cars from the Australian market as part of a global recall. This is due to a fire-risk caused from an electrical short and overheating battery [1]. Locally there had no been incidents however there has been 15 fires across the US, South Korea, Canada, Finland and Austria [2].

This is not just for electric vehicles that utilize Lithium-ion batteries, but also other companies are seeing the risks connected with these batteries. LG Energy Solutions, a battery manufacturer previously called LG Chem, has recalled a range of household batteries since they can catch fire from overheating. More than 5000 units were pulled as a result [1].

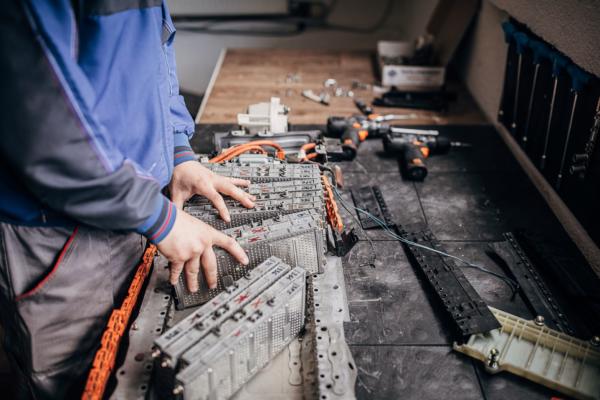

These two events have led to thousands of Lithium-ion batteries being processed in Melbourne by battery recyclers. This is a challenge as processing Li-ion batteries of these type are a new and complex task for Australia. They come with a fire-risk and contain potentially toxic materials that are hazardous for the environment if handled incorrectly.

ABC News visited EcoBatt, Hyundai’s confirmed battery recycler in Australia, who are dealing with the emergence of Lithium battery waste. Electric car batteries can be large and Hyundai’s one was a size of a dining table. The workers had to pull it apart with power tools and a fire extinguisher nearby which is one ordeal. However EcoBatt’s experience is in smaller lead-acid based batteries within electric appliances. Not only are their size a challenge to break down to a processing size, it requires careful handling and dismantling with the risk of fires, electrocution, short circuits and thermal runaways.

Despite plans to deal with this kind of waste, it was anticipated that they would start receiving them over the next few years. The recalls made it arrive early instead and there may be more Lithium-ion batteries than expected. CSIRO, the Commonwealth Scientific & Industrial Research Organisation, predict the waste stream from electric vehicles could reach 180,000 tonnes by 2036 in Australia alone [1].

What sets Lithium-ion batteries apart from others is the electrolyte system which allows electrical charge to pass between the two terminals. This consists of flammable and combustible organic solvents and when lithium salt is dissolved in it, it becomes corrosive and toxic. It also emits hydrofluoric acid when it contact with water.

It poses not just a fire-risk to users but also to recyclers.

Earlier this year Tesla had their own factory near Geelong in flames after a coolant leak lead into a short circuit fire [3]. In 2019 Envirostream had one of its factories lit up in flames whose official fire report noted the probable cause as a short circuit in a battery to be recycled. Like EcoBatt, Envirostream are seeing a rise in lithium-ion batteries as they are handling the home energy storage batteries recalled by LG Energy Solutions and the batteries of Mitsubishi hybrid cars.

There is currently no national plan for recycling and it is on the individual companies to recover the battery through their individual programs. The BSC will implement a product recovery scheme for smaller non-lithium batteries found in remotes, appliances and watches. They are looking to include the larger scale of batteries from electric cars and home storage though it will not be easy to do so.

Bluelab Design is the only Australian distributor of ETAP Lighting’s emergency and exit lighting range. The batteries used are Nickel-Metal-Hydride (NiMH) which are proven to be more stable across a range of temperatures compared to Lithium-ion, is easier to recycle and has been proven to be more environmentally friendly.

In Europe there is a Battery Directive that bans the use of cadmium in batteries with emergency lighting being one of the exceptions. ETAP Lighting adopted the NiMH batteries that are not only Cadmium-free, but consume less energy and 50% more compact. ETAP Lighting is focused on circular solutions and green safety, which is about maximum sustainability in emergency lighting. Their leaflet on these concepts can be read here.

As lighting designers and manufacturers, Bluelab Design are confident in their products and proud to distribute them. We can provide lighting design services and consultancy on how to best utilize ETAP Lighting for your future projects.

Contact us now for more information.

References:

[1] “Electric cars and home batteries are already posing a waste problem in Australia. Here’s why”; Emilia Terzon, The Business in ABC News; full article here (https://www.abc.net.au/news/2021-10-25/electric-car-solar-battery-storage-waste-recycling/100564234)

[2] “The $1.13 billion recall: Hyundai to replace batteries in 82,000 electric cars due to fire risk”; Joshua Dowling; Drive; full article here (https://www.drive.com.au/news/the-1-13-billion-recall-hyundai-to-replace-batteries-in-82000-electric-cars-due-to-fire-risk/)

[3] “Fire at Tesla giant battery project near Geelong was likely caused by coolant leak, investigation finds”; Leanne Wong, ABC News; full article here (https://www.abc.net.au/news/2021-09-28/fire-at-tesla-giant-battery-project-near-geelong-investigation/100496688)