Up-Cycling in Lighting

Maintenance by renovating LED Lighting

With LED becoming the prime light source in every type of building, most LED products have no solution for end of life. More disturbing, is that lighting products have become a consumable item, where throwing out and replacing lighting fixtures is standard, this also extends to Emergency and Exit Lighting. The Exit and Emergency test cycles offer a lucrative secondary industry with an additional constant source of income for Lighting suppliers. Most Emergency and Exit Lighting products offer inadequate self-testing and monitoring systems (voltage test). The product indicator will alert a fault in the product and not offer a diagnosis. The cost for maintenance to explore the product fault out weighs the cost to simply replace. ETAP Lighting evacuation lighting is the only product in the Asia Pacific offering a comprehensive self-testing and self-diagnosing built in test system ‘EST+’ read more.. Similarly with lighting products, when a product fails it is easier for contractors to replace rather than repair, with many products not designed for repair and for that matter longevity. We have normalised and accepted fast lighting similar to fashion and furniture.

40% of landfill in Australia is construction waste according to Australian Government, Department of Environment and Climate Change NSW. With very little commitment to longevity (LLMF), recycled materials within product development, or products that are able to be easily renovated at the end of the LED or LED driver life.

Longevity – LLMF

The life cycle of a luminaire can be tested in an age report or “obsolescence test” to produce a TM21 report. The TM21 report results will be displayed as ‘Light Loss Maintenance Factor’ LLMF. The LLMF will offer the percentage of light that will be retained after 50’000 hours.

eg. LLMF=88% @ 50khrs

The above LLMF can be translated as 88% of the light output (lumens) are retained after 50’000 hours and the product will loose 12% of the initial luminous flux. For lighting designers this equates to 12% deducted from a rooms lighting calculation. If a room is calculated to 360 Lux on the working plane, after 50khrs that room will be left with 316.8 Lux on the working plane.

Many companies in Australia will not provide TM21 reports and/or not have had their products tested. Rather, lighting companies will offer a LM80. LM80 reports are produced by LED chip manufacturers. The chips are batch tested in a lab in ideal conditions to support the LED chip. it does not include a luminaire. An LM80 report cannot be relied upon to report the life of the LED within a lighting fixture, many variable come into play in product design and production.

Most products in Australia are not engineered to maximise the chip health for longevity. LED needs to run cool (<65° @T-junction), well designed products will use heat sinks, layered aluminium housings and run with low a current driver (milliamps – mA). Many lighting manufacturers will run their lighting products with a higher current mA to a higher light output to be seemingly more efficient – Lumens per Watt Lm/W. By doing this, the chip life is sacrificed. “The candle that burns twice as bright, burns half as long” Lao Tzu.

Furthermore, many LED lighting products have very little airflow to support LED chip health. Manufacturers opting for compact housings, injection molded housings, reduced aluminium to save production/product costs. These cost effective products do not last and are often manufactured with materials that cannot be recycled. Read more on LED facts..

It is prudent to ask for manufacturers to supply a TM21 report. ETAP Lighting offer LLMF=95%@50Khrs and above on many of their products, being cleverly designed for aesthetics and to last.

Of course Exit and Emergency lighting suffers the same bad ‘fast lighting’ culture an the cost of building maintenance, the end user and the environment. Evacuation Lighting in Australia commonly use Lithium batteries because they can be re-charged quickly. To achieve maximum life of these batteries they should be stored in a cool space and discharged regularly (same as our mobile phones). we store Evacuation lighting batteries in the small housings, plastic injection molded with little heat dissipation, and ceiling cavities. The batteries are rarely discharged for evacuation nor in mandatory testing. Of course this will reduce the battery life. Exit and Emergency lighting companies offer warranties that do not include Batteries or LED. Read more on Evacuation health

Lithium Batteries have been the root cause of many building fires.

Choosing product that will last and can be renovated to last the life of the interior installation. ETAP use NiMH batteries (Nickel Metal Hydride Batteries) same as Toyota hybrid car technology, that CAN be recycled up to 95%. NiMH are more stable and can be stored in warmer environments safely and without reducing the life of the battery. The EST+ testing system support battery health with a 13 week cycle of battery discharge that will also report compliant battery life. With the EST+ feature inbuilt on every ETAP Lighting evacuation product to support the longevity of the product, ETAP include Batteries and LED’s within their warranties. ETAP Lighting produce easily maintainable products to LAST.

Follow this link to see our K9 Exit battery replacement..

Circularity in lighting.

Choosing product that have recycled materials and CAN be recycled and/or renovated.

It is not enough to just use a recycled cardboard box to wrap lighting products.

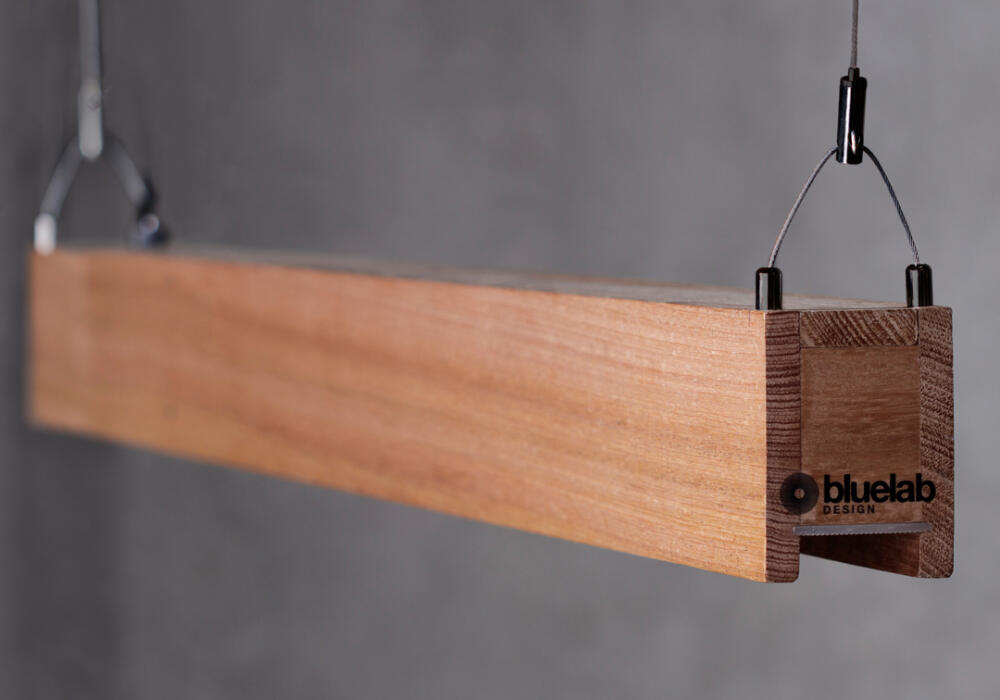

Using materials in lighting design and construction that are recycled and can be recycled like Bluelab Design’s Truss reclaimed timber range made from locally sources reclaimed hardwood timber.

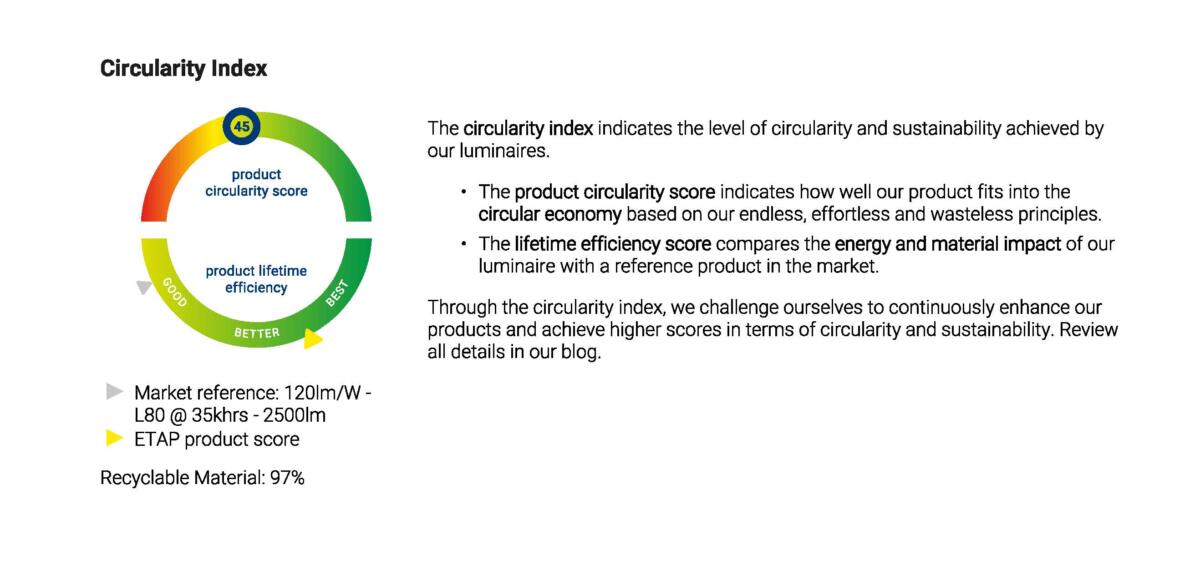

ETAP lighting products offer a ‘circularity wheel’ to rate the lifetime efficiency and product circularity score. read more.. Within ETAP Lighting’s product data sheets, the percentage of recycled material used to produce each product is advertised. The U3 troffer uses 97% recycled materials.

While Lighting is commonly disposed of, so is Exit and Emergency lighting. Disposing evacuation lighting has the added problem of disposing of the battery. Nearly all Exit and Emergency lighting products in Australia use Lithium batteries. Lithium Batteries cannot be recycled currently, CSIRO are working to find a solution to extract the valuable minerals found in Lithium batteries for re-use. Currently Lithium batteries, when they are disposed of responsibly, will be discharged to reduce instability, with no solution for Lithium in Australia our Lithium waste is shipped off shore to be disposed of. Lithium is a Toxic waste.

Renovation or up-cycling products.

Things were a little simpler with incandescent and fluorescent lighting. When a product failed it was generally the lamps. The lamp was changed, the glass or shade cleaned making the light as new. Fluorescent Lamps or tubes were regularly changed along with starters returning the products lux level to original performance.

With the emergence and rapid advancement of LED technology, there was no solution for repair or ongoing maintenance (apart from LED bulbs). For the last 25 years since the steady increase in lighting industry, the question ‘What happens when the LED fails?’ has been dodged. Lighting companies have preferred to discuss the length of time the product may last, rather than what happens when it doesn’t – the only answer being ‘replacement’.

LED Lighting and LED Evacuation Lighting have become disposable products similar to fast furniture and fast fashion adding to land fill. LED Lighting reluctantly accepted as a commodity with lighting companies happily replacing lighting fixtures every few years. The cheap downlights commonly used in multi-residential developments will be one of the first products to be replaced due to failure. These products are cheap and not designed for longevity.

Bluelab Design and ETAP Lighting are leading the way with conversations and products offered that are designed to be renovated/up-cycled.

Products that have no pot rivets, welds, glue to hold in components, no injection moulded housings that cannot be opened easily making repairs impossible.

ETAP Lighting and Bluelab Design design products with plug and play connection to components for easy onsite repairs and renovation. After years of product use, the LED and/or driver can be replaced for an ‘as new’ solution. If there is a catastrophic fail within the luminiare components the solution comes to play. Either way, the products are repaired or renovated rather than being disposed of.

This is particularly important in retail, warehouses and call centres where the artificial lighting is being used 24/7 and lighting will invariably fail in 3 years. Lighting replacement and upgrades expensive ongoing necessity. ETAP Lighting provide a range of industrial lighting and commercial lighting for retail with the ability to easily replace gear trays for a renewed lighting system.

The renovatable feature is offered across ETAP Lighting and Bluelab Design’s range. Including ETAP Lighting’s highly efficient LEY Architectural extruded lighting.

Read more on Circularity in Exits and Emergency Lighting product..

Circularity in building & lighting upgrades

From Fluorescent lighting to premium LED optics in minutes.

Many buildings in Australasian cities still have fluorescent luminaires as office lighting. The TBar Troffer is rapidly being replaced presently with new fittings. Many of the existing fluoro troffers have quality housing, return air slots linked to the office air flow, imperial Tbar grids or cut to purpose plaster for the old luminaire.

To replace the lighting system can be costly with new fittings, installation, return air commissioning, new ceiling or ceiling repairs. Some project require custom LED to match the existing ceiling cut outs. The replacement of office lighting adds to land fill, CO2 emissions in recycling and fabrication of new products.

Bluelab Design and ETAP Lighting have developed a premium range of LED ‘inserts’ for upgrades. These inserts are designed to easily upgrade office lighting for a quality LED lighting solution while retaining the existing housing. By using the existing housing it simplifies the upgrade.

Bluelab Design released the Infinity Premium insert in 2025. Locally designed, locally produced for Premium LED lighting upgrades – lighting Refurbishment that is inexpensive, quick and has an optimal lighting outcome. Read more on the Infinity..

ETAP Lighting lead the European market in Lighting updates with C-LAAS offering circular lighting as a service. While C-LAAS is not available in Australia presently, we can certainly offer ETAP Lighting’s award winning refurbished lighting expertise. Read more on lighting renovation

By offering renovation solutions for our customers, we lower land fill waste, CO2 emissions, maintenance costs, installation and environmental impacts, while delivering a premium LED lighting solution that is affordable and cheaper than most budgeted products. Renovation products and renovatable products are another step toward responsible building design for the future.

Speak to Bluelab Design about circular products.